Real Flexible Wood Sheet Tennâge® "Sewable Wood"

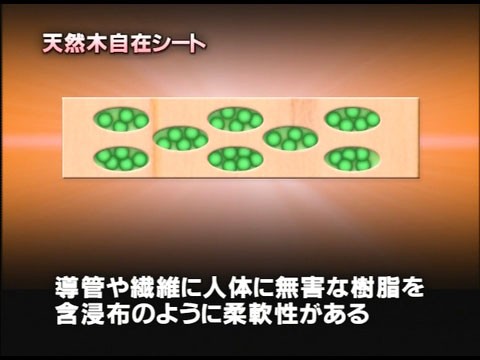

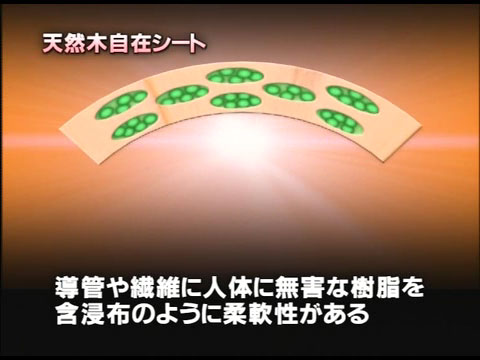

Concept/Structure of Tennâge®

We impregnate special resins into thin sliced wood sheet to make it flexible and durable enough for repeat bending and holding.

|

|

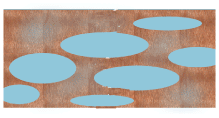

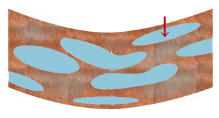

Water relieves stress concentration |

| Live Wood – There is water in conducting vessels, pores and cells. | ||

|

|

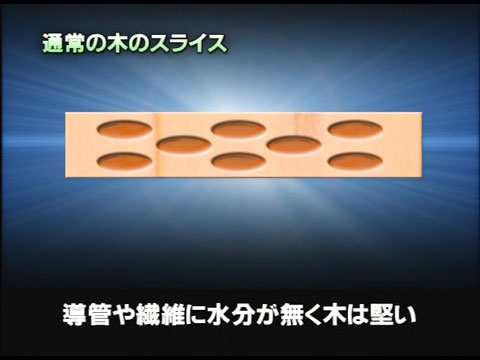

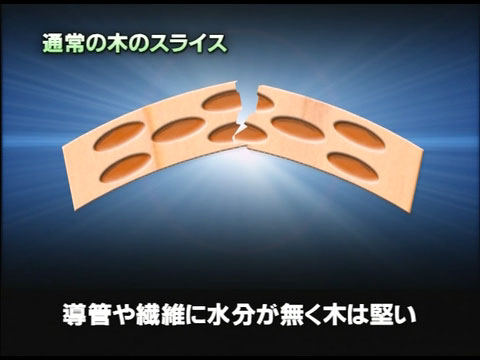

Stress concentration resulting cracking |

| Cut/Dried Wood – No water in conducting vessels, pores and cells. | ||

|

|

Resin relieves stress concentration |

| Tennâge® – There is resins in conducting vessels, pores and cells. | ||

When a wood is cut, it dries up and loses all waters in conducting vessels, pores and cells. Therefore, when it is thin sliced, it easily cracks and not bendable. We impregnate special resins into conducting vessels, pores and cells of a thin sliced real wood with our special technique. Those resins inside of conducting vessels, pores and cells relieve stress concentration. Therefore, our Tennâge® wood sheet is flexible and durable enough for bending and folding.

Manufacturing Process of Tennâge®

Our Tennâge® are all made in Japan. The special technique and process of impregnating special resins into real wood sheet are all done in Japanese factory.

Our unique technique and process of real wood sheet are covered by many media, such as "Technique-Japanese Power in Manufacturing" by TV Tokyo-WNS (World Business Satellite). Please see more details for the list of TV Broadcasting.

Contact

Please contact us if you need more detailed information. » Contact