Wood Veneer Basics

Natural wood veneer processing has unique appeal and modern value.

The benefits of using real wood veneer:

- Property of real wood:

- The real wood veneer means that each veneers has one-of-a-kind wood grains and color. The variations and special designs of real wood veneers can never be achieved by man-made alternatives.

- All the warmth and depth of genuine wood:

- Real and natural wood finishes add natural warmth and ambience to our technology saturated lives.

- Rich and Elegant Look:

- Wood is a premium decorative finish that adds a rich and elegant look over plastic products. With Our IMW method, wood veneer can be molded to fit most shapes.

- Maximizes nature's resources

- Each meter of lumber can typically provide 1,000 slices veneers. Veneer is a highly efficient use of lumber. The industry is committed to sustainable forest resources.

Wood veneer --- Our oldest, yet most modern material.

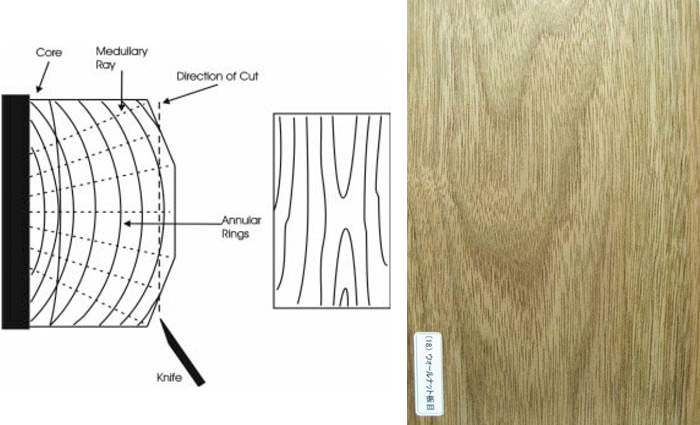

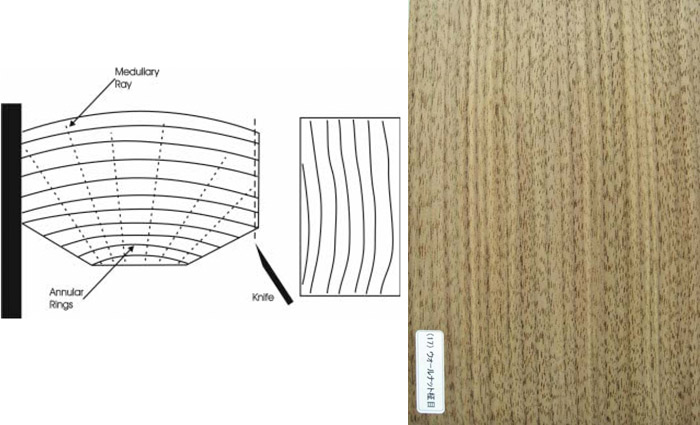

Cutting method for timber to veneer

Most decorative veneers selected by ZEROONE-IMW are crown cut (flat sliced) or quarter cut (straight sliced) by slicing in either a vertical or horizontal slicer, or in a stay log (semi-rotary) veneer lathe. Some decorative veneers are rotary peeled, resulting in veneer grain patterns that are variegated. Manufacturing of decorative wood veneers is a costly and time consuming process, only the highest quality logs with minimal internal defects are selected.

Crown cutting (Flat sliced):

Crown cutting (Flat sliced) / Flat sliced Walnut veneer:

Quarter cutting (Straight sliced):

Quarter cutting (Straight sliced) / Straight sliced Walnut veneer: